Probitas Manufacturing Technologies, LLC began operations in 2006 to satisfy the needs of the customer whose requirements for high quality parts and timely deliveries are of the utmost importance. Probitas is committed to bringing the technology and skills needed to satisfy the customer.

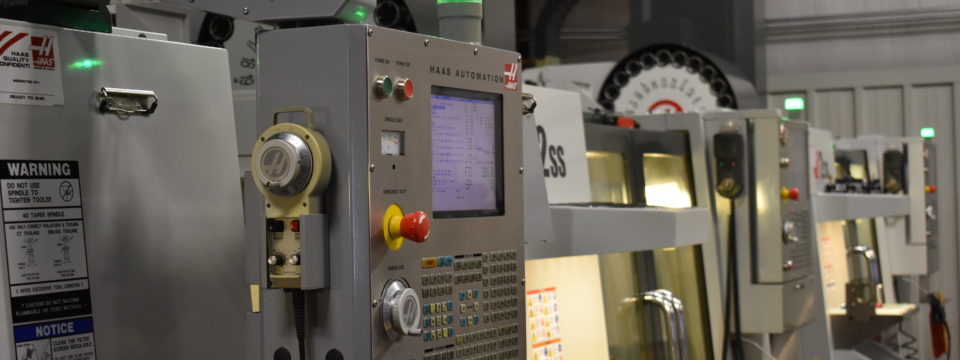

Probitas processes orders on High Speed CNC Machining Centers with 12,000 rpm spindles and 4 axis capability. These machines are capable of holding the precise tolerances required by the Probitas customer; while providing material removal rates necessary to maintain productivity thereby assuring timely deliveries. With machining envelopes up to X42” x Y20” x Z24”, the current capability for production is small to mid size CNC milled parts.

Probitas is capable of working with electronic models and datasets supplied by customers. Mastercam 2021 is used for programming of the CNC equipment. This software can import solid models from customers CAD systems or Probitas can create models from customer furnished drawings. Using customer furnished models can shorten the lead time for new orders. Because solid models help eliminate drawing interpretation errors, they can also help improve the accuracy and completeness of the first part produced. Probitas also has the capability to use the same solid models for inspection of the completed part using PCDMIS CAD measurement software.

Probitas has invested in up-to-date inspection equipment and software. All parts manufactured by Probitas will undergo inspection on a Brown and Sharpe Micro-Hite DCC CMM. This machine has a measuring envelope of X17.” x Y19.” x Z15.”. Upon request, customers will receive a computer generated first article or serialized 100% inspection report of their parts.

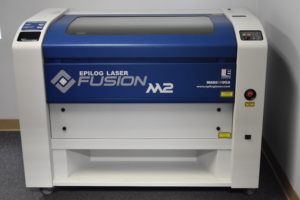

Probitas has the ability to mark or engrave parts as necessary through the use of an Epilog Fusion M2 Laser, which utilizes both C02 and fiber sources. The marking area of this laser is 18″ x 24″.

Owner, John Hanna, brings to Probitas over 43 years of experience in the precision manufacturing industry. His experience includes project engineering, programming of CNC machining centers, and operation of CNC machining centers. John is known within the industry for his ability to work with difficult materials such as titanium, inconel and various stainless steels including 17-4, 15-5 and 13-8. John looks forward to meeting with you personally and discussing your precision parts needs.